About us

AIRtronic® - Quality since 1995

AIRtronic® manufactures welding and electromechanical products - primarily for the rail vehicle industry.

Due to the requirements of rail vehicle operators concerning on-site production our customers produce at various locations around the world.

Therefore, we also supply to the rail vehicle industry worldwide.

Our customers' satisfaction and trust is important to us

We strive to establish long-term cooperation with

our customers based on partnership. Therefore, we are committed to always meeting our customers' requirements. For us, this is not just about specified product features and

the delivery agreement, it's also about competent and

friendly advice.

Compliance with legal and regulatory requirements

To ensure contractual and legal requirements,

we undertake to comply with the applicable legal and regulatory requirements regarding product safety.

Partnership cooperation with our suppliers

Our suppliers' quality performance is part of our product quality which we provide to our customers at the highest technical level. Therefore, we set clear, understandable specifications and always maintain open communication with our suppliers.

Competent and satisfied employees

Each employee knows their responsibilities and the required specifications. If the need arises for changes or an expansion of competencies, these will be communicated internally or externally.

Correct and prevent deviations

We strive to get things right from the start. We prevent possible errors using internal specifications. Should errors nevertheless become apparent, these will be corrected as early as possible and on a permanent basis.

Striving for continuous improvement

It is important to us to strengthen our innovation and competitiveness. In addition to our commitment to the technical and qualitative improvement of our products, we also organise our processes using a certified quality management system.

SINCE 1995

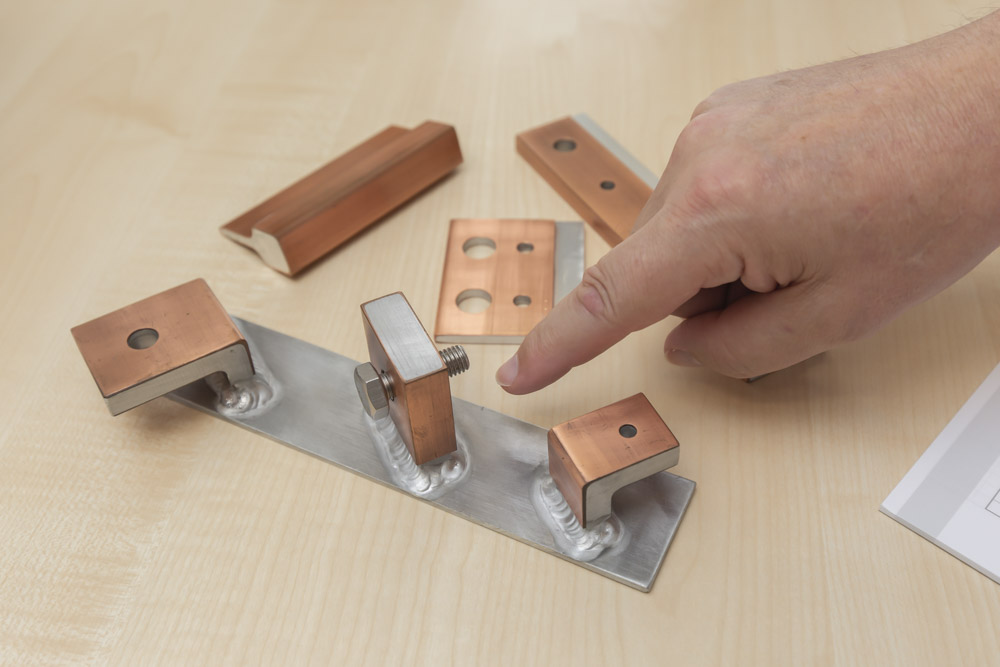

Our company founders were occupied with the problem of the electrical connection of aluminium and copper. The solution was found in pressure grouting. Here, copper and aluminium are joined together at a pressure of 5 tonnes and a gas-tight bond is created between the copper and aluminium.

2002

AIRtronic® was founded when the AIRcunal product was ready for series production.

2003

The contact surfaces of aluminium grounding eyelets are coated with brass. The production of stainless steel earthing products begins.

2005

Customised cable assemblies are made available.

2006

Move to new offices in Carl-Bosch-Straße.

2011

AIRtronic® has connectors (Sub-D and M12) also manufactured for the rail vehicle industry.

2014

Beginning of the production of USB products for rail vehicles.

2015

ISO 9001 certification.

2022

AIRtronic® is exhibiting at InnoTrans for the first time with its own stand.